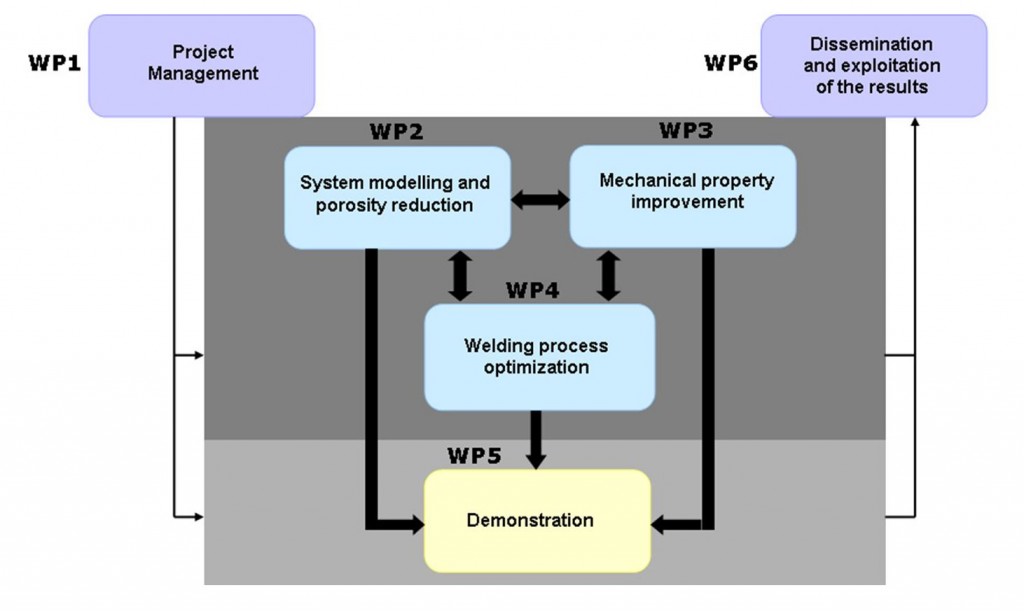

Workplan

Given that this project is centred on a technological need and challenge that is experienced by a large community of European SMEs, the work plan has been based on a bottom-up, industry driven approach:

WP1 (Coordination and management).

This WP covers all those aspects of project management and control, which will ensure that the project successfully achieves its stated objectives on time and within budget.

WP2 (System modelling and porosity reduction).

This WP focuses on the VPDC parameters that can be directly related to porosity formation and development of good practices to avoid its formation (numerical simulation, HPDC process parameter, lubrication). Statistical methods will be used for identifying the main parameters affecting porosity formation.

WP3 (Mechanical property improvement).

In this WP all aspects of mechanical properties that are not related to porosity will be optimized: the new recycled alloy(s) composition, the melt and heat treatment and a suitable control for the new melt treatments (Si modification and degassing) developed. HPDC process parameters have to be adapted to the new recycled alloy.

WP4 (Welding process optimization).

The objective of this WP is to establish an appropriate lubrication technique and welding process that allows using the new recycled alloy(s) for structural applications in vehicles

WP5 (Demonstration).

The objective of this WP is to demonstrate the effectiveness of the new VPDC technologies and new recycled alloy(s) developed in the project in each participating SME foundry under industrial conditions. The demonstrators will be validated by x-ray tomography, metallographic analysis, tensile testing and welding test.

WP6 (Dissemination and exploitation of project results).

An important part of the proposed project is the dissemination and exploitation of the results reached within the project. Training activities for the SME foundry personnel are also foreseen.

The research leading to these results has received funding from the European Union`s Seventh Framework Programme managed by REA – Research Executive Agency -http://ec.europe.eu/research/rea (FP/2007-2013) under Grant Agreement number 315506

The research leading to these results has received funding from the European Union`s Seventh Framework Programme managed by REA – Research Executive Agency -http://ec.europe.eu/research/rea (FP/2007-2013) under Grant Agreement number 315506